The first time I stood on the sands of the Saqqara necropolis, the sheer scale of the Step Pyramid of Djoser felt less like an ancient ruin and more like a direct challenge to modern understanding. The dry Egyptian air hummed with a history so deep it was almost tangible. My mind, trained in modern project management and engineering principles, immediately began racing, trying to deconstruct the scene. It wasn't just a pile of stones; it was a testament to organized genius. The question that echoed in my thoughts wasn't just "how," but "how, with what they had?" This firsthand encounter moved beyond textbook knowledge, sparking a profound curiosity into the practical, innovative, and surprisingly sophisticated saqqara pyramid construction technology that made this world-first possible.

Contents

- 1 The Genesis of a Revolution: Understanding the Saqqara Pyramid Construction Technology's Origins

- 2 Quarrying and Sourcing Materials: The Foundational Challenge of Saqqara Pyramid Construction Technology

- 3 Transportation and Lifting: Overcoming Gravity with Saqqara Pyramid Construction Technology

- 4 The Architectural Genius of Imhotep: A Deep Dive into Saqqara Pyramid Construction Technology

- 5 Labor and Logistics: The Human Engine Behind Saqqara Pyramid Construction Technology

- 6 Legacy and Influence: How Saqqara Pyramid Construction Technology Shaped Future Monuments

- 7 Frequently Asked Questions

- 8 References

- 9 Conclusion: The Enduring Genius of Ancient Engineering

The Genesis of a Revolution: Understanding the Saqqara Pyramid Construction Technology's Origins

To truly grasp the brilliance behind the Step Pyramid, one must first understand what came before it. The innovation wasn't born in a vacuum; it was an evolutionary leap built upon centuries of tradition. The analysis of this transition from simple tomb to monumental structure is fundamental to decoding the saqqara pyramid construction technology and the mind of its architect, Imhotep.

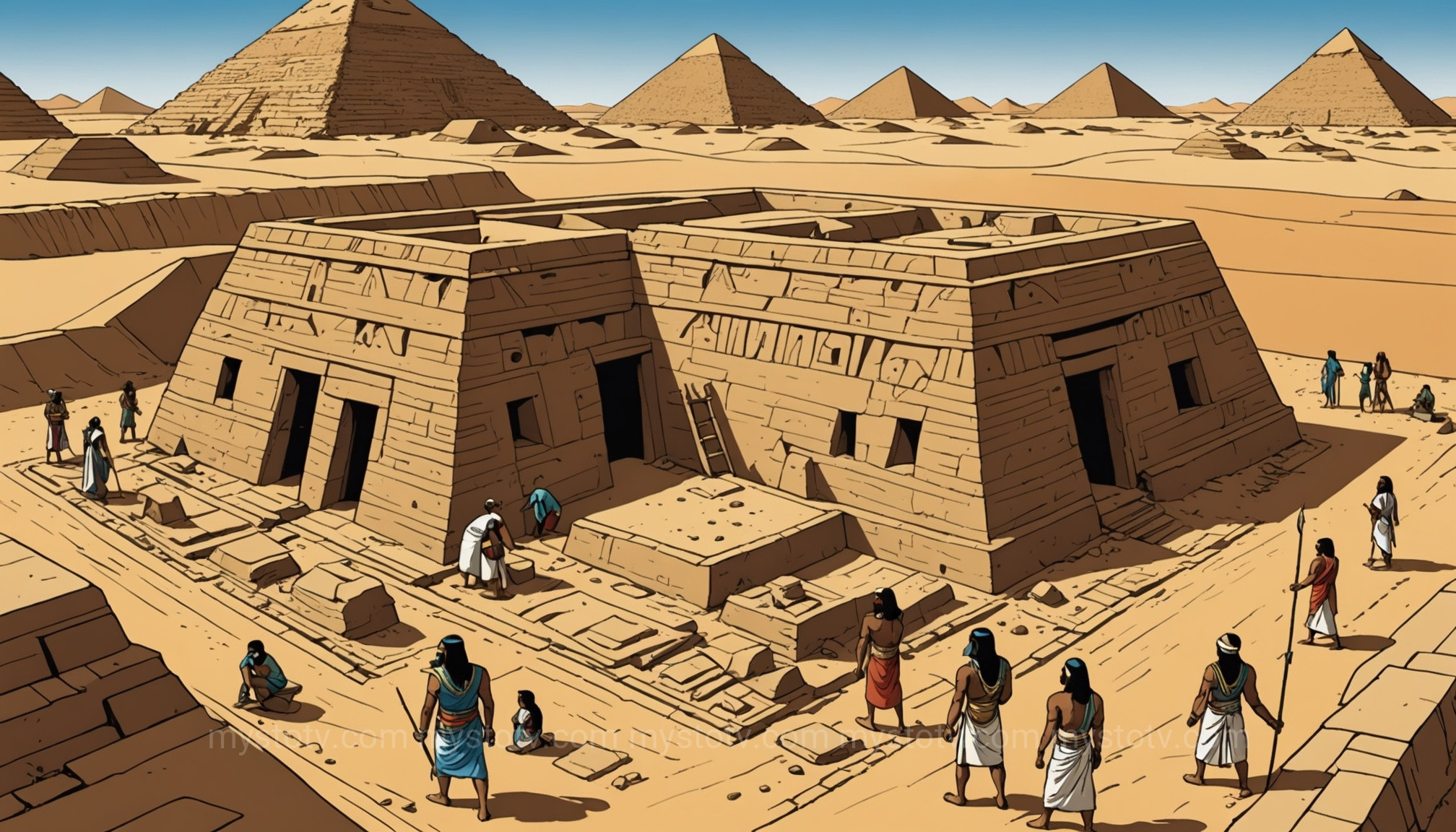

From Traditional Mastaba to Monumental Vision

For generations, Egyptian pharaohs and nobles were interred in mastabas. These were single-story, rectangular structures with flat roofs and inward-sloping sides, typically built from mudbrick. Below ground, a vertical shaft led to a burial chamber, sealed to protect the deceased and their worldly possessions for the afterlife. The mastaba was functional, symbolic, and deeply ingrained in funerary tradition. It represented the "eternal house" and the primordial mound from which life emerged in Egyptian creation myths. However, its scale was earthly, its materials perishable.

King Djoser's reign during the Third Dynasty (c. 2670 BCE) marked a pivotal moment. His vizier and chief architect, Imhotep, envisioned something far grander. He didn't just want an eternal house; he wanted a stairway to the heavens. This conceptual shift was the catalyst. The analysis suggests that the initial plan was for a large, square stone mastaba, already a significant upgrade from the traditional mudbrick rectangle. This in itself was an ambitious undertaking, substituting a durable, monumental material—stone—for the first time on such a massive scale.

Imhotep's Innovative Leap: The Stacking Principle

The true genius of the saqqara pyramid construction technology is revealed in the subsequent phases of construction. Evidence uncovered by archaeologists, most notably Jean-Philippe Lauer who dedicated his life to Saqqara, shows that the pyramid was not built in one continuous effort but in a series of six distinct stages. After the initial square mastaba (M1) was completed, it was enlarged (M2), and then further extended (M3). It was at this point that the revolutionary idea took shape.

Instead of stopping at a larger, flat-topped mastaba, Imhotep began to build smaller mastaba-like structures on top of the existing one. This created a four-stepped structure (P1), which was later expanded into the final six-stepped pyramid (P2) we see today, reaching a height of roughly 62 meters (204 feet). This "stacking" method was a practical solution to achieving height and stability with the available tools. It allowed workers to build in manageable layers, using the top of each completed step as a platform for the next. This iterative design process is a hallmark of sophisticated engineering, demonstrating a clear ability to plan, execute, and modify a complex project over several years.

Quarrying and Sourcing Materials: The Foundational Challenge of Saqqara Pyramid Construction Technology

Before a single block could be laid, an immense logistical operation had to be conceived and executed. The choice of materials and the methods of their extraction were the bedrock of the entire project. The success of the saqqara pyramid construction technology depended entirely on the ability to procure millions of tons of stone from the Egyptian landscape.

Sourcing the Core: Local Limestone Quarries

The bulk of the Step Pyramid's core is composed of locally quarried limestone. These blocks were relatively rough-hewn, as they would not be visible in the final structure. Geologists have identified that these quarries were likely located very near the construction site, within the Saqqara plateau itself. This was a critical logistical advantage, minimizing the distance these heavy blocks needed to be transported.

Quarrying techniques, while primitive by modern standards, were remarkably effective. Workers would identify fissures in the limestone beds. They would then carve channels into the rock using hard dolerite pounders and less durable copper chisels (which had to be constantly re-sharpened). Once the channels were deep enough, they would insert wooden wedges into them. These wedges were then soaked with water. As the wood absorbed the water and expanded, it exerted immense pressure, cracking the limestone and freeing large blocks from the rock face. This clever use of natural principles showcases the ingenuity inherent in the era's engineering.

The Prized Casing: Fine Tura Limestone

While the core was made of local stone, the exterior was originally clad in a pristine, white casing of fine Tura limestone. This material was highly prized for its quality and bright appearance, which would have made the pyramid gleam brilliantly in the Egyptian sun. The quarries for this stone were located at Tura, on the opposite bank of the Nile River. This presented a significant transportation challenge.

The blocks of Tura limestone had to be quarried with greater precision, then loaded onto large wooden barges for the journey across the Nile. After being offloaded, they would have been hauled up to the Saqqara plateau. This bi-sourcing strategy—using local, lower-quality material for the hidden core and importing high-quality material for the visible exterior—is a clear example of efficient resource management. It demonstrates a sophisticated understanding of materials science and logistics, central tenets of the saqqara pyramid construction technology.

Transportation and Lifting: Overcoming Gravity with Saqqara Pyramid Construction Technology

Once quarried, the colossal task of moving and lifting millions of tons of stone began. This phase of the project is often the subject of the most speculation and awe. Analysis of the archaeological evidence and experimental archaeology provides a clear picture of how the ancient Egyptians likely conquered the forces of physics using manpower and clever engineering, defining the practical application of saqqara pyramid construction technology.

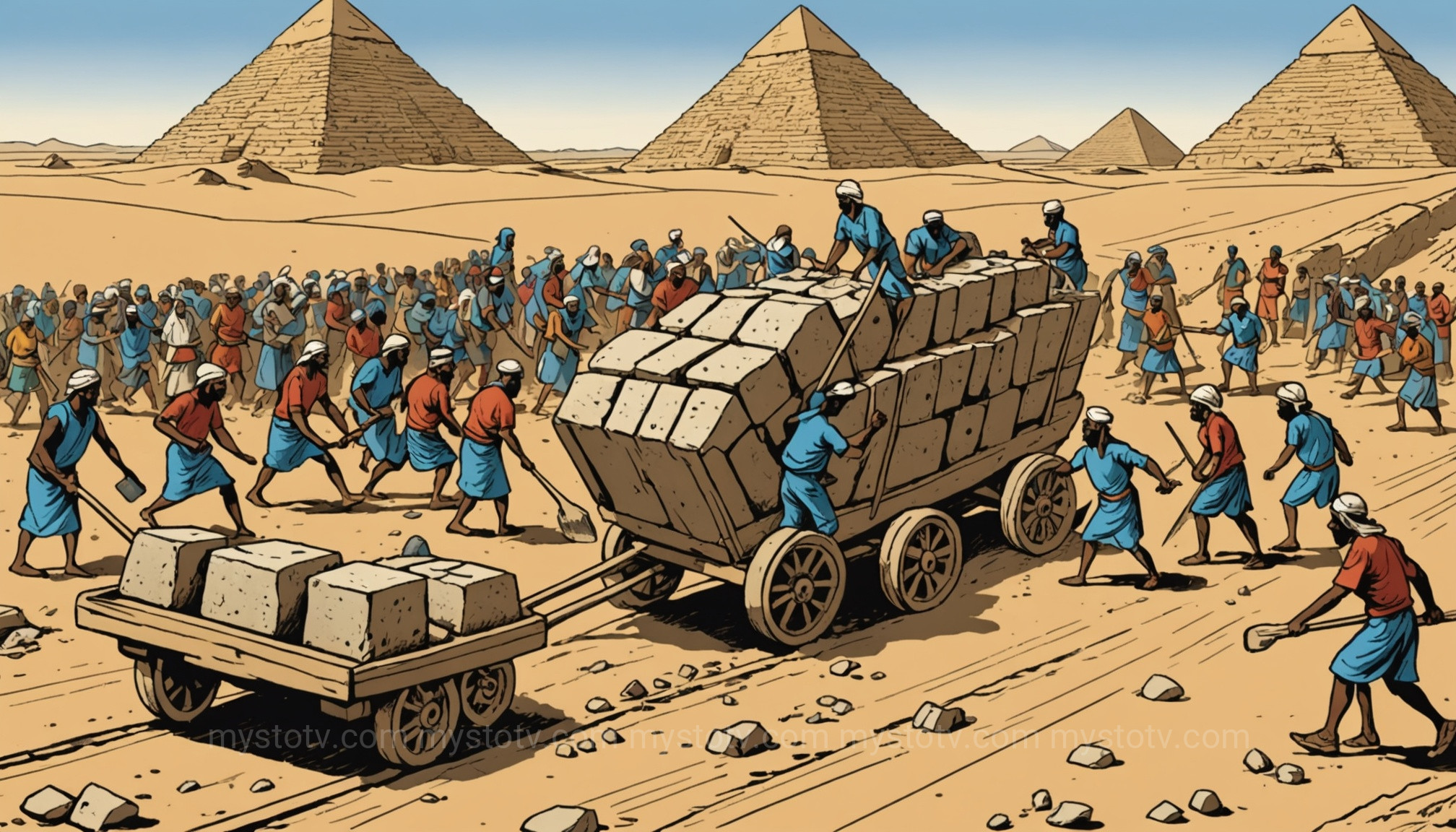

The Role of Sledges, Ropes, and Manpower

Wheeled vehicles were not suitable for moving heavy loads over soft sand or uneven terrain. The Egyptians' solution was the wooden sledge. Stone blocks, some weighing several tons, were loaded onto these sledges and pulled by large teams of workers using strong ropes made from papyrus or palm fibers. Tomb paintings from later periods, such as the tomb of Djehutihotep, explicitly depict this method.

A key innovation to aid this process was lubrication. Experiments have shown that wetting the sand in front of the sledge's runners dramatically reduces the friction, halving the amount of force required to pull the load. This simple yet brilliant technique would have been essential for moving the vast quantities of stone needed for the pyramid. It represents a practical, science-based solution that maximized the efficiency of the available labor force.

The Great Ramp Debate

Lifting the blocks to increasing heights was the greatest challenge. The most widely accepted theory is the use of construction ramps. However, the exact configuration of these ramps is still debated by Egyptologists. Several possibilities exist for the saqqara pyramid construction technology:

- Linear Ramps: A long, straight ramp extending from the pyramid's base outwards. The main drawback of this design is that as the pyramid grew taller, the ramp would need to become impractically long to maintain a manageable gradient. For Saqqara's final height, such a ramp would have required more material than the pyramid itself.

- Spiral or Encircling Ramps: A ramp that wrapped around the pyramid as it was built. This design is more space-efficient and would have allowed for the continuous delivery of materials to the working level. Evidence of similar construction ramps has been found at other, unfinished pyramid sites, lending credibility to this theory.

- Internal Ramps: A more recent theory, proposed by architect Jean-Pierre Houdin for the Great Pyramid, suggests a ramp may have been built within the pyramid's core structure. While compelling, there is less direct physical evidence for this at Saqqara.

The most plausible analysis for Saqqara suggests a combination of methods. Shorter, linear supply ramps were likely used for the lower levels, possibly transitioning to smaller, encircling ramps or levering systems for the upper, smaller steps. The ability to adapt lifting techniques as the structure grew is another testament to the flexible and problem-solving nature of Imhotep's engineering plan. This innovative building plan was key to the project's success.

The Architectural Genius of Imhotep: A Deep Dive into Saqqara Pyramid Construction Technology

Beyond the brute force of quarrying and hauling, the Step Pyramid is a monument to intellectual prowess and meticulous planning. Imhotep was not just a builder; he was a true architect and systems engineer. A deeper analysis of the design choices reveals a sophisticated understanding of structural mechanics, project management, and religious symbolism, all integral to the saqqara pyramid construction technology.

A Multi-Phased Masterpiece

As mentioned earlier, the pyramid's construction in six distinct stages is one of its most fascinating aspects. This iterative approach allowed for problem-solving and design evolution in real-time. For instance, the shift from a square mastaba to a stepped pyramid required significant structural considerations. The builders at Saqqara used smaller, more manageable blocks compared to the colossal megaliths of Giza, which were likely easier to handle with the available lifting technology. Furthermore, the blocks were laid with a slight inward incline, directing the weight and stress towards the center of the structure, thereby increasing its stability. This was a crucial engineering insight that prevented the massive structure from collapsing under its own weight.

Engineering for Stability and Symbolism

Beneath the pyramid lies a complex labyrinth of tunnels, shafts, and chambers, extending nearly 28 meters deep and running for almost 6 kilometers. This subterranean complex was the true heart of the funerary monument, housing the king's burial chamber, storage rooms for grave goods, and galleries thought to be for the king's ka (spirit). The burial chamber itself was constructed of granite, a much harder stone brought from Aswan, far to the south, showcasing their ability to work with different and more challenging materials.

The engineering of this underground network was as complex as the pyramid above it. It required careful planning to ensure the tunnels would not collapse under the immense pressure of the superstructure. The very design of the six steps was deeply symbolic, representing a literal stairway for the deceased pharaoh's soul to ascend and join the circumpolar stars—the eternal, undying gods in the northern sky. Thus, the saqqara pyramid construction technology was a perfect marriage of form and function, where every engineering choice was also imbued with deep religious meaning.

Labor and Logistics: The Human Engine Behind Saqqara Pyramid Construction Technology

A project of this magnitude could not have been completed without a large, well-organized, and motivated workforce. The romanticized Hollywood image of slaves being whipped into submission is a myth that has been thoroughly debunked by modern archaeology. The reality of the labor force is a story of skilled citizens, societal organization, and logistical prowess, a crucial component of the saqqara pyramid construction technology.

Skilled Artisans, Not Slaves

Archaeological evidence from worker villages near later pyramid sites, like Giza, reveals that the builders were skilled Egyptian laborers. They lived in organized communities, were provided with food (including meat, bread, and beer), shelter, and medical care. Skeletons of workers show evidence of healed fractures and other work-related injuries, indicating they received care and were valued members of the project.

This was likely a system of national service, or corvée labor, where citizens would work on state projects for a portion of the year, particularly during the Nile's annual inundation when agricultural work was impossible. This system mobilized a massive national workforce. The teams were likely divided into competing gangs, fostering a sense of camaraderie and rivalry that would have boosted productivity. These were not slaves but respected artisans and builders contributing to a national, religious project of immense importance.

Organizing the Workforce

The logistics of housing, feeding, and supplying tools for a workforce of thousands was a monumental task in itself. It required a sophisticated bureaucracy to manage supply chains for food, timber for sledges and ramps, copper for chisels, and stone from various quarries. Imhotep's role would have extended far beyond architectural design; he would have been the master project manager, overseeing every facet of this complex operation.

The successful coordination of so many moving parts—from quarrying teams to transport crews, from masons to the officials managing supplies—is perhaps the most impressive aspect of the saqqara pyramid construction technology. It demonstrates a highly structured society with a clear chain of command and an advanced understanding of large-scale project management, long before such concepts were formalized in the modern era.

Legacy and Influence: How Saqqara Pyramid Construction Technology Shaped Future Monuments

The Step Pyramid was not an endpoint; it was the beginning of the "Age of the Pyramids." It served as a crucial prototype, a grand experiment in stone that provided the lessons necessary for the even more ambitious projects that followed. The legacy of the saqqara pyramid construction technology is evident in every subsequent pyramid built in Egypt.

The Blueprint for Giza

The innovations at Saqqara were the direct precursors to the true, smooth-sided pyramids. The transition can be seen at sites like Meidum and Dahshur, where pharaoh Sneferu (Djoser's successor) experimented with pyramid design. His "Bent Pyramid" at Dahshur clearly shows a mid-construction change in angle, likely due to stability concerns—a lesson learned from the steep sides of earlier designs. His subsequent "Red Pyramid" was the first successful true pyramid, a direct result of perfecting the techniques first developed for Djoser.

These later pyramids utilized much larger core blocks, an efficiency improvement on the Saqqara model. However, the fundamental principles—mass quarrying, river transport for casing stones, the use of ramps, and a highly organized workforce—were all established at Saqqara. Without the trial-and-error process undertaken by Imhotep, the wonders of Giza would not have been possible.

Lessons Learned in Stone

Saqqara taught Egyptian builders invaluable lessons about structural stability, material stress, and the sheer logistics of monument building. They learned about the importance of a solid foundation, the method of inclining courses for stability, and the need for a precisely engineered casing to complete the structure. The entire complex at Saqqara, with its surrounding courtyards, temples, and dummy buildings for the Heb-Sed festival, also established the blueprint for the standard pyramid complex that would be replicated for centuries.

In essence, the Step Pyramid was Egypt's stone-built university of engineering. It was a bold declaration of human potential and the birth of monumental architecture. Its influence stretched across millennia, making the exploration of saqqara pyramid construction technology a journey into the very dawn of engineering.

Frequently Asked Questions

Here are some common questions about the specifics of the construction process at Saqqara.

What specific tools were used in the Saqqara pyramid construction technology?

The toolkit was surprisingly simple yet effective. The primary tools included dolerite pounders (a very hard igneous rock) for rough shaping and quarrying, copper chisels and saws for more precise cutting of limestone (which had to be frequently re-sharpened as copper is relatively soft), and wooden levers for maneuvering blocks. For measurement and alignment, they used simple but accurate tools like plumb bobs for vertical lines, set squares for right angles, and long cubit rods for measuring length.

How long did it take to build the Step Pyramid of Djoser?

While exact records don't exist, historians and Egyptologists estimate the construction spanned most of King Djoser's reign, which lasted approximately 19 to 29 years. The multi-stage nature of the construction, starting as a mastaba and evolving into a six-step pyramid, supports this extended timeframe. It was a continuous project of expansion and modification.

Was the Saqqara pyramid ever completed as originally intended?

Yes, it is widely believed that the six-step pyramid we see today was the final, completed version as envisioned by Imhotep in the project's later stages. The entire complex, including the surrounding courtyards and temples, was finished and used for King Djoser's funerary cult. However, the casing of fine Tura limestone was largely plundered in antiquity, which is why we now see the rougher core blocks of the steps.

Why is Saqqara's pyramid a "Step Pyramid" and not a "true" pyramid?

A "Step Pyramid" is structurally a stack of mastabas of decreasing size, creating a distinct step-like appearance. A "true" pyramid, like those at Giza, has smooth, flat sides that meet at a single apex. The Step Pyramid represents an evolutionary midpoint between the flat-topped mastaba and the true pyramid. The engineering knowledge to create a stable, smooth-sided structure had not yet been perfected; that breakthrough would come with Sneferu's Red Pyramid at Dahshur.

References

- Lehner, Mark. The Complete Pyramids: Solving the Ancient Mysteries. Thames & Hudson, 2008.

- Verner, Miroslav. The Pyramids: The Mystery, Culture, and Science of Egypt's Great Monuments. Grove Press, 2001.

- Brier, Bob, and Hoyt, Hobbs. Ancient Egypt: Everyday Life in the Land of the Nile. Sterling, 2009.

- Hawass, Zahi. "The Discovery of the Tombs of the Pyramid Builders at Giza." The World of the Pharaohs, 1997.

- Lauer, Jean-Philippe. Saqqara: The Royal Cemetery of Memphis, Excavations and Discoveries since 1850. Charles Scribner's Sons, 1976.

Conclusion: The Enduring Genius of Ancient Engineering

The Step Pyramid of Saqqara is more than just the world's first large-scale stone building; it is a masterclass in problem-solving, project management, and innovation. Standing as a silent monument on the desert plateau, it tells a story of a pivotal moment in human history when ambition and ingenuity converged. The analysis of the saqqara pyramid construction technology reveals a process that was systematic, adaptable, and profoundly intelligent. From the clever quarrying techniques and logistical mastery to the revolutionary architectural concept of a stepped structure, every element speaks to the genius of Imhotep and the organized power of the Egyptian state. Unlocking its secrets reminds us that the foundations of modern engineering were laid not in steel and concrete, but in limestone, copper, and the boundless potential of the human mind.